There are numerous features that contribute to a basement’s ability to be a calm and serene place when considering it in any home. There may be a lot of noise in your basement, therefore the only way to get some peace is to learn how to soundproof a basement ceiling!

How to Soundproof a Basement Ceiling? Soundproofing a basement ceiling can best be started by adding mass. To stop the impact noise from above, you must use the robust channel to disconnect the roof from the floor joists.

There are a number of factors at play in the first prevalence of sound in a basement. Changes might occur quickly by focusing on specific problems.

best way to soundproof a basement ceiling

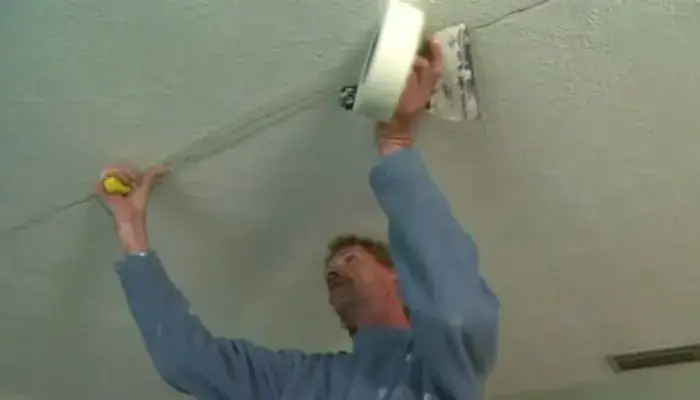

1. Seal any gaps or cracks

This is the fundamental rule in soundproofing if you know what I mean. Whatever space you’re trying to soundproof doesn’t matter.

Always attempt to fill any holes first. No exception applies to the basement ceiling.

The biggest problem with allowing sound to enter your basement is gaps. Unfortunately, there are a few holes and cracks in the majority of basement ceilings.

It shouldn’t be difficult to seal them. You can quickly tell the difference by using caulking seals.

No amount of soundproofing will completely stop the sound if the gaps are not sealed.

Closing down the cracks and openings should be your top priority if you want to get the best possible basement noise reduction.

2. Adding insulation

Acoustic insulation:

- On its own, acoustic insulation or acoustic foam is the least effective of the soundproofing methods. It is typically used in wall and ceiling cavities to absorb and lessen sound intensity in order to minimize the passage of airborne sounds.

- In summary, ceiling cavity soundproof insulation will help to lessen airborne noises. For impact noises, though, it won’t be much use.

- I advise using this remedy as a supplement to other ones rather than as a stand-alone fix.

- You can utilize a variety of products, however, the ones listed below all have very good NRC ratings. The noise reduction coefficient (NRC) measures a material’s ability to absorb sound waves.

- Dropped ceilings and open ceilings both benefit from insulation. You would have to take out the drywall, insulate the cavity, and then put it back up to insulate a finished ceiling.

- For existing walls, blown-in insulation is a possibility, but it is a little more expensive. You have to buy materials and pay labor charges, which can add up, as I detail in my post on soundproofing existing walls.

- If at all feasible, use insulation that is 3″ thick, and make sure it is not packed firmly inside the hollow. The best material for both effectiveness and fire resistance is mineral wool.

Fiberglass batts:

- A common type of insulation that can be utilized to help insulate a basement ceiling is fiberglass insulation batts. They are constructed from flexible, fibrous materials made of glass strands that have been weaved together. By absorbing and damping sound waves, they can aid in reducing sound transmission when fitted between the joists of the basement ceiling.

- It’s crucial to utilize a thicker fiberglass batt than what is generally used for insulation when installing fiberglass batts for soundproofing. For soundproofing, a thickness of R-19 or greater is advised. For best effectiveness, it’s also crucial to check that the batts fit tightly, without any cavities or gaps, between the joists.

- It’s also important to keep in mind that while fiberglass batts can aid in reducing sound transmission, depending on the exact sources of noise and the design of your home, they might not be the best option for soundproofing a basement ceiling. Fiberglass batts can be more successful when used in conjunction with other soundproofing techniques, such as adding a layer of drywall or caulking crevices and gaps. To find the best answer for your unique case, speak with a qualified contractor.

Spray foam insulation:

- Another choice for soundproofing a basement ceiling is spray foam insulation. It is a kind of insulation that may be used to fill up small spaces and difficult-to-reach places since it can be sprayed onto a surface using a specialized tool. Spray foam insulation helps to fill any gaps or cracks that may be present in the ceiling while also providing significant insulating value. As a result, sound waves can’t travel through the ceiling, reducing sound transmission.

- Spray foam insulation comes in two varieties: open-cell and closed-cell. Compared to closed-cell spray foam insulation, open-cell is less expensive and less dense, but it might not be as soundproof. Spray foam insulation made of closed-cell cells is denser and more expensive but offers superior insulation value and has the potential to be more soundproof.

- Use a product that is specifically made for soundproofing when putting spray foam insulation for soundproofing, and make sure it is applied evenly and thickly enough. For soundproofing, a thickness of at least 2 inches is advised.

- It’s also important to keep in mind that while spray foam insulation can aid in reducing sound transmission, depending on the exact sources of noise and the design of your home, it might not be the best option for soundproofing a basement ceiling. Spray foam insulation can be more successful when used in conjunction with other soundproofing techniques, such as adding drywall or building a floating floor. To find the best answer for your unique case, speak with a qualified contractor.

Blown-in insulation:

- Another choice for soundproofing a basement ceiling is blown-in insulation. It is a specific kind of insulation that is blown into the void between the basement ceiling joists with the aid of specialized equipment. It can be used to fill in any openings or voids in the ceiling and works to dampen and absorb sound waves, which helps to limit sound transmission.

- It’s crucial to use a product that is specially made for soundproofing when putting blown-in insulation for soundproofing and to make sure that it is placed uniformly and at the required thickness. For soundproofing, a thickness of at least R-19 or greater is advised.

- Cellulose insulation, the most popular type of blown-in insulation, is derived from recycled paper, offers good insulation value, and has the potential to be more successful at soundproofing than fiberglass batts. Another is mineral wool insulation, it’s created from rock or slag and it has better soundproofing capabilities than cellulose.

- It’s also important to keep in mind that while blown-in insulation might aid in reducing sound transmission, depending on the precise sources of noise and the design of your home, it might not be the best option for soundproofing a basement ceiling. Blowing in insulation can be more effective when used in conjunction with other soundproofing techniques like installing drywall or caulking cracks and gaps.

3. Adding a layer of drywall

- Although drywall has a relatively low STC rating (about 38) on its own, it serves as a good foundation for other, more efficient materials.

- Furthermore, drywall is very affordable and widely accessible, making it a wonderful place to start for soundproofing a basement ceiling on a budget.

- The use of a Green Glue Damping Compound is the strategy I would advise.

- The STC should be increased to about 49 because it works really well. A dampening compound is particularly efficient against low-frequency sounds when added. The acoustic sealant should not be confused with the Green Glue damping compound. This substance has a sound-dampening effect when placed between two stiff layers.

- Green Glue advises using 2 tubes per 4 x 8′ piece of drywall when utilized in this manner. Simply apply it liberally on the sheet, wait 15 minutes for it to start curing, and then fix the drywall into place.

4. Using sound-absorbing materials

- Using sound-absorbing materials on a basement ceiling can be an effective method for soundproofing. Acoustic panels or tiles, for example, are made to absorb sound waves and lessen the volume of sound that travels through the ceiling.

- It’s crucial to make sure that sound-absorbing materials are put in correctly. This comprises:

- Direct installation on the ceiling will aid in sound absorption by stopping sound waves before they reach the joists.

- utilizing an adequate quantity of materials Utilizing sufficient materials will efficiently absorb sound waves. Depending on the particular goods and the size of the room, this will change.

5. Building a floating floor

- Soundproofing a basement can be done by creating a floating floor over the existing ceiling. A floor that is “floating” on top of the supporting structure rather than being anchored to it is known as a floating floor. By putting a barrier between the sound source and the living area, can aid in sound isolation and transmission reduction.

- It’s crucial to choose materials that are made for soundproofing while constructing a floating floor, such as cork or acoustical underlayment. Compared to conventional flooring materials, these materials are denser and more porous, which helps to absorb and reduce sound waves.

how to Deal with pipe and duct work for soundproofing?

Pipes and ductwork can produce enough low-level noise to be bothersome, as we briefly mentioned before. The full length of the pipes connected to any faucet in your home are capable of generating vibrations that can fill entire rooms if you turn it on. When your furnace starts up, the same thing could occur. You have a large source of sound when pipes and ductwork vibrate because everything related to them vibrates as well. By keeping them at bay, your new basement living quarters will have a more relaxed and pleasant atmosphere.

We get there by decoupling or separating them from the other surfaces they come into contact with and adding insulation. If your ceiling is sealed, this step is difficult; however, soundproofing a ceiling with exposed joists is simple.

You may stop those vibrations from spreading to other materials by wrapping your pipes and ducts in an insulating coating and fastening them with clamps that disconnect them from the surrounding structure. Additionally, it absorbs a significant portion of the sound waves generated by the pipes and ductwork before they ever reach our ears.

what is the type of noise pollution?

The two primary categories of noise pollution are the most logical place to start. Since the first level of a house is typically the busiest, you’ll find both in the basement.

There are two categories of noise pollution:

- Airborne noise

- Impact noise

Airborne Noise:

The definition of airborne noise is self-explanatory: sound waves travel through the air after leaving their source. A fraction of the wave’s energy flows through the structure when it makes contact with it. Airborne sound waves are split into two parts: absorbed and reflected.

Insofar as it is simpler to add new levels to the structure than to change it, airborne noises are easier to block. You need to make structural adjustments that interfere with or alter the direction of the sound waves in order to prevent impact noises.

Impact Noise:

When an object collides with a structure, impact noise is produced. As a result, vibrations caused by mechanical energy are transmitted into the structure. Sound waves then emerge from the opposite side of them.

Due to the fact that the basement ceiling is the first floor of the building, impact noises will frequently be a problem in basements. Typically, this section sees the most traffic.

how to Soundproofing a Finished Basement Ceiling?

Anyone working on a soundproofing project is typically in danger if a basement ceiling is already finished and appears to be a completed project.

Although it’s hoped that whoever originally constructed the ceiling did some kind of soundproofing, that may not be the case.

If the drywall ceiling simply isn’t doing the job in terms of soundproofing, there is always the alternative of ripping it down.

It is normally expensive to rebuild, but that is not a problem. Adding something to the exposed ceiling itself is a simple solution that many people find far more sensible.

Panels are a fantastic choice for soundproofing because they can be made to look like they belong in the room’s layout.

They can be permanently or temporarily fastened to prevent unintentional falling. Always keep in mind that gravity is working against anything attached to a ceiling when dealing with ceilings.

In order to avoid errors, it must be done appropriately. This is particularly true if there is a lot of movement above, as that may cause the ceiling to tremble and force anything to fall.

Sound can be controlled even better by concealing mass loaded vinyl or other thin material behind panels.

Even if it’s not always the best circumstance, finished basements typically require a sport in general. When building a new structure, much focus is placed on taking sound into consideration.

A completed ceiling is perhaps the ultimate goal if the objective is to make the space appear to be an actual part of the house.

Some people may prefer the unfinished appearance, but a finished ceiling will help to conceal any soundproofing that has been done.

They won’t have the final coat of drywall covering everything, no matter how much work is done on the ceiling.

FAQs about How to Soundproof a Basement Ceiling

Q1: Does acoustic treatment reduce noise?

Ans: There are several useful justifications for acoustically treating your rooms. Unlike soundproofing, it won’t lessen sound transmission into and out of the room, but it can do so by absorbing sound that would otherwise bounce around the room.

q2: What is the cheapest way to soundproof a basement ceiling?

Ans: Soundproofing a basement ceiling with mass-loaded vinyl or acoustic insulation is the least expensive option. These materials can efficiently prevent sound transmission and are simple to place between the ceiling joists. Acoustic caulk can also aid in reducing sound transmission by filling in any holes or fractures in the ceiling. Use of soundproofing paint, which can be applied on the surface of the ceiling, is an additional affordable solution.

q3: Can you soundproof an existing basement ceiling?

Ans: Yes, it is possible to soundproof a basement ceiling that already exists. Installing mass-loaded vinyl or acoustic insulation between the ceiling joists is one way to do this. This is a simple and affordable option that can effectively prevent sound transmission. Installing a suspended ceiling is an additional choice because it might provide an air gap that lessens sound transmission.

q4: How do I stop noise coming through my basement ceiling?

Ans: The sound is stopped and absorbed by adding acoustic insulation between the ceiling joist and the soundproof board. The amount of sound that passes through the ceiling is greatly reduced by the use of sound isolation clips, sound insulation slabs, and acoustic plasterboards.

tell us in the comment as per you this information is use full.

Additionally, don’t forget to read the other post on ideas for making houses, which will definitely provide you with an insightful and helpful perspective.