Hello Friends

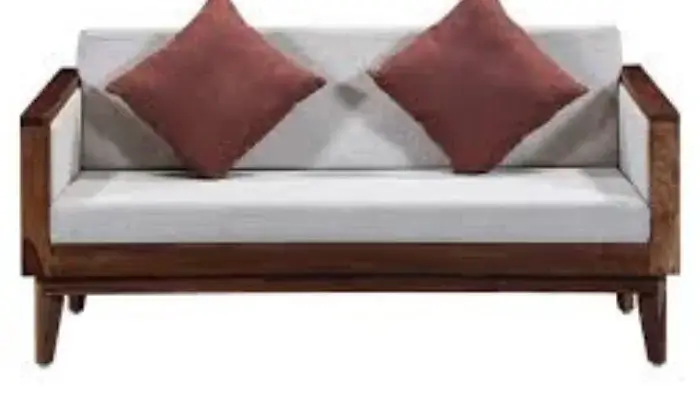

Do you want to learn How To Make A Sofa Step By Step At Home ? Here is Best ideas for making it at the comfort of your home. Do check it,

The first home improvement project that springs to mind is most likely not a couch. One of the most crucial pieces of furniture in any living room is the couch. We really don’t dare to consider it as a prospective DIY project because it is the center point of the space.

When I went online to see how difficult it would be to make one, I discovered there aren’t many resources outlining the procedure and explaining why certain components were required, why a dimension was created in this way, or why a couch had springs on the bottom.

You would think that there would be a few websites that show plans and blueprints in the era of DIY and Indestructible, but I could only find one from Australia. I’ll therefore detail my research in the process of building a couch and delving deeply into the world of furniture creation in the hopes that someone else may find this information helpful.

Required Tools For How To Make A Sofa Step By Step At Home ?

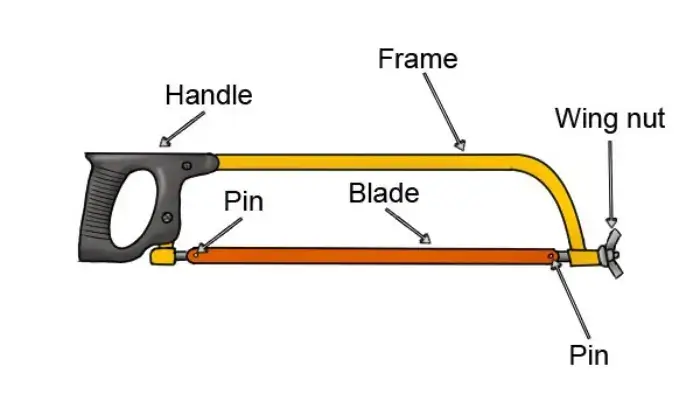

1. Hacksaw

A hacksaw is a hand-powered, small-toothed saw used for cutting metal pipes, rods, brackets, etc. Hacksaws can also cut through plastic. The hacksaw has a U-shaped frame and a handle at one end. Hacksaws have small pins at each end of the frame that receive a blade.

2. Chisel Set

A chisel is a cutting tool with sharp edges that is used to chip away at stone, wood, or metal by pushing or pounding the rear of the tool against the object. It consists of a thin, rectangular block of metal with a bevel or wedge-shaped end and, occasionally, a handle on the other.

3. Rubber Mallet

A rubber mallet is a small, hammer-like implement with a handle made of wood or fiberglass and a head made of hard plastic or molded rubber. When you require a gentler blow than even a wooden mallet might produce, you utilize rubber mallets, also known as soft mallets.

4. Sawhorse

A beam with four legs is called a “saw-horse” and is used to support a board or plank while it is being sawed. A plank can be supported by two sawhorses, creating a scaffold. It is also referred to as a mule in some areas, while a short sawhorse is called a pony. The names are derived from the frame’s equine-like form.

5. Heavy duty steel triangle ruler

A ruler, also known as a rule or line gauge, is a tool used in engineering and construction as well as the fields of geometry and technical drawing.

6. Webbing Stretcher

A webbing stretcher is an upholstery tool used to stretch webbing. Traditional wooden webbing stretcher. Contents. 1 Chair upholstery; 2 Modern webbing’s

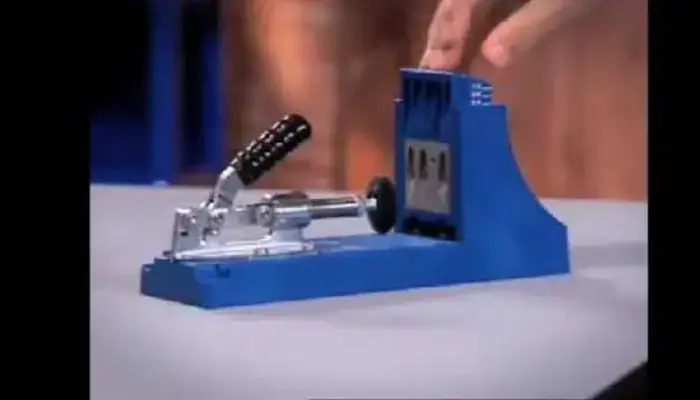

7. Pocket Hole Jig System with Face Clamp

Classic Face Clamps are excellent for many other shop and project activities that need for firm clamping without marring. They are designed for producing absolutely flush Kreg Joints. Large clamp pads on these clamps properly distribute gripping force while holding components flush during assembly.

8. Staining Brushes

Natural bristle brushes are among the best for applying stain since they can be cleaned and reused for numerous applications. With 100 percent acrylic and acrylic or oil stains, synthetic bristles work best. They won’t sag like natural bristles will.

Required Material For How To Make A Sofa Step By Step At Home ?

1. USB Coupler (F/F) A/B + USB Cable

For connecting an existing USB cable to a USB 3.0 or 2.0 cable to a computer, smartphone, tablet, or other device, the Cable Matters USB 3.0 Female Coupler is a crucial tool. Your current cables won’t suffer from the SuperSpeed USB 3.0 data transmission rate of up to 5 Gbps.

The Universal Serial Bus (USB) is an industry standard that specifies cables, connections, and protocols for interfacing (connecting) computers, peripherals, and other computers, as well as for connection, communication, and power supply.

2. Foam seat cushions and back cushions

Any foam used as padding in upholstered or fabric-covered furniture is referred to as upholstery foam. Although latex foam is also used, flexible polyurethane foam (FPF) is the most common type of upholstery foam. For indoor, outdoor, and maritime furniture, various types of upholstery foam are employed.

3. Elasbelt 2 inch 164 foot roll

Upholstery webbing is a strong, closely woven fabric used to make items such as straps and belts and support the seats of upholstered chairs.

4. Microfiber Shell fabric

Synthetic fiber with a diameter of less than ten micrometers that is finer than one denier or decitex/thread is known as microfiber (or microfiber). A silk strand is roughly one denier and a sixth the diameter of a human hair.

5. Upholstery Zippers + Zipper Slides

This method for sewing upholstery zippers is great for home decor projects like cushions. The tutorial includes a video, written directions, and photos.

6. 2″x 4″x 96″ wooden studs / 2″x 6″x 96″ wooden studs

Today, there are many different sorts of studs with varying forms, shapes, and finishes that are appropriate for various types of furniture and décor. These include tacks, nail heads, and rivets.

Boards called studs serve as framing components for your couch and support the walls. How widely apart are the studs in my sofa, you may be wondering? They always run between the top and bottom of the frame and are spaced at either 16 or 24 inches on center (measured from center to center).

7. Wood stain and seal

Most stains should be sealed to prevent bleeding. After smoothing the stained wood, apply a sealer coat of thinned shellac, sanding sealer, or other appropriate sealer. Do not use shellac with NGR or water-base stains.

8. Pocket Screws

When I initially learned about pocket joinery, coarse-thread pocket screws worked best in softer woods like pine, cedar, and poplar as well as plywood; use fine-thread screws for hardwoods. Pocket joinery is a method of connecting pieces of wood by driving screws into angled holes.

Best Tips For How To Make A Sofa Step By Step At Home ?

1. Making Wooden Frame

It’s time to construct the sofa now that we have the design, the measurements, the necessary tools, and the supplies. I started by cutting the boards to size using my design’s specifications. To make sure everything would fit, I double-checked and revised my designs.

I sliced once after following the adage “measure twice, cut once.” I determined the distance, marked it, drew a line through it, then measured it once again to confirm that it was accurate. I measured the finished piece after cutting to make sure I cut it to length. Even if there is a lot of measuring, it is preferable to cutting everything at once and having nothing fit.

I used conventional mortise and tenon connections to create the upper portion of the base. I chose this route because mechanical joints make sense for furniture because they are extremely sturdy in all directions. While it took significantly longer than using screws alone, the satisfaction of seeing everything fit was much greater. Naturally, I probably over-engineered this portion, but it’s better to have a very solid base than something that might crumble.

I utilized pocket screws to conceal the screws from the side on the other portions of the sofa. I have serious concerns regarding the claim that pocket screws are equally as durable as mortise and tenon joints. They still function properly for the rest of the sofa and are rather sturdy.

2. Webbing on the sofa

The cushions for the top will be made after the frame is finished, but first we must attach the webbing to the sofa.

The webbing was stretched after being stapled at one end using the webbing stretching tool. Since I didn’t want to drill any more holes than necessary.

I chose to use a conventional webbing stretcher rather than one that uses metal nails. The strength of the webbing prevents manual stretching. When stretched properly, it has a pleasant drumming sound. Even though I may have overdone it by using 9–10 staples per base.

I’m confident they won’t come undone. Since there shouldn’t be as much tension on the back (and I don’t want to use too many staples), I used less on that area. For further stability, I woven each strap through the others.

Making the cushions for the top may now begin because the webbing is in place. Since they arrive vacuum sealed and compacted, I ordered 6 foam cushions—3 for the seats and 3 for the back—and let them decompress for a day. I started cleaning the covers with the microfiber cloth as it was decompressing.

The seat cover has 24 dimensions “(The cut fabric is 1/2″ extra to account for the 1/4″ stitching margin.) W x 28″ L x 6″ H. The back coverings measured 24″ wide by 16″ high by 5″ deep, sloping slightly downward to 6″ in size. The foam seat cushion has dimensions of 25″ x 29″ x 6.5” “so as to complete the cover.

It’s not a big concern, but it does prevent me from placing the arm rest on the opposite side. To fill out the seat coverings, buy larger cushions; however, be sure to adjust the size so that it meets the required length. Note to self (and others).

As a further side note, if you create the covers 1/2″ too small, the foam within the cover will begin to bow, so double-check your measurements.

You must place the foam in a sealed plastic bag, attach a vacuum to it, and begin compressing the foam in order to get it to fit inside the cover. It would be difficult to cram the cushions’ strong foam—which I purchased specifically for them—into them without compressing it. I quickly threw it into the cover once it was compacted to prevent it from expanding again, and then I slowly removed the plastic bag to use for the others.

I cut each piece from the enormous 10 yard microfiber roll after measuring each side Plus 1/2″ for stitching. Fortunately, I had barely enough to create all the pillows and barely any more.

3. Time to Finishing

The wood must be stained and sealed as the last step to give it a neat appearance. Since the stain I’m using only needs one coat, I used a sealant when the stain set. Sadly, there aren’t any images because I didn’t want to ruin my camera by trying to snap shots. In essence, it’s like painting with conventional paint, with the exception that you have to wipe it down after letting it dry. Simply adhere to the directions on the cans.

In order to match the walls, I also sewed three 16″ accent pillows to go on the couch, going from light blue to dark blue. These seemed so simple to create after spending so much time making the pillows.

So there you have it—a brief introduction of sofa construction. I’ve been working on it for two months on the weekends, and now I understand why nice couches cost about $2,000 each.

These require a great deal of labor and specialized equipment to build everything. You can try this if you have the time and are willing to make a few mistakes when building a sofa for the first time. It definitely takes longer than you anticipate, and the cost of starting from scratch is equivalent to the price of a typical sofa. This can be enjoyable to do if you have the tools or have plans to make something other than a sofa.

What will I do after this? I might construct a coffee table to match my new sofa. I feel like I can furnish everything now that I have the necessary tools. Since I have everything recorded, I could also make a more in-depth plan for this sofa, but for the time being, this is a nice overall overview.

FAQs About How To Make A Sofa Step By Step At Home ? best way

Can you build your own sofa?

Since you’re basically building your own couch from scratch you get to decide the dimensions, shape and everything else. You can start by picking your couch cushions. Once you find a design and size you like, you can build the frame of the couch around them.

Which material is best for sofa set?

Best Sofa Material Types

#1: Leather. Leather is easy to clean. An age-old favourite, leather is a no-brainer when it comes to sofas of any style. …

#2: Linen. A tough and rough textile. …

#3: Cotton. Woven cotton fabric is durable. …

#4: Wool. Wool blends are durable and warm. …

Leather. Classic brown leather.

Is it cheaper to make your own sofa?

If you are buying cheap laminate furniture that is made to last a year or two, then yes, your real wood furniture might end up being just as expensive. But you’re going to have to throw about that cheap furniture and replace it.

What type of fabric is used for sofas?

The different types of upholstery fabric include cotton, linen, wool, leather, acetate, hemp, silk, polyester, polypropylene, acrylic, rayon, and nylon. Upholstery fabric can be constructed from one type of yarn or a blend of yarns. Choosing the correct upholstery fabric will ensure the longevity of your furniture.

Tell Us In The Comments As Per You this guidance is use full